Product Design Consulting for Hazardous Location

We help you with product design, safety evaluation, and get you certification with our partner labs (NRTLs) for IECEx, ATEX, UL, CSA, UKCA, CE and CB approvals

We help you with product design, safety evaluation, and get you certification with our partner labs (NRTLs) for IECEx, ATEX, UL, CSA, UKCA, CE and CB approvals

Comprehensive ATEX compliance, IECEx certification, and UL CSA solutions for explosive atmosphere applications

European ATEX directive 2014/34/EU compliance for explosive atmosphere equipment, covering gas zones 0, 1, 2 and dust zones 20, 21, 22 with CE marking

International IECEx explosive atmosphere certification for global market access, including IEC 60079 standards compliance and testing coordination

North American hazardous location classification per NEC as per class and division scheme. This includes Class I, II, III, and Division 1 or 2

Additional engineering and consulting services to support your safety and compliance needs

Comprehensive DHA studies per NFPA 652 to identify combustible dust hazards, evaluate risks, and recommend protection measures for your facility

Electromagnetic compatibility testing and consulting services to ensure your equipment meets EMC standards and regulatory requirements for reliable operation

Custom engineering solutions for intrinsic safety, flameproof enclosures, and specialized equipment design for hazardous location applications

Safety and compliance testing for non-hazardous environments including IEC 61010, IEC 62368, FCC Part 15, UL 2089, CSA standards for general use equipment and consumer electronics

Technical training on Ex standards, hazardous area classification, and intrinsic safety principles for panel shops, system integrators, and engineering teams to ensure compliant installations

Process hazard analysis, HAZOP studies, area classification studies, layer of protection analysis (LOPA), and quantitative risk assessment for industrial facility safety management

We work with all major certification bodies and international standards

Our expertise in ATEX, IECEx, North America(UL, CSA), and UKCA standards for explosive atmosphere compliance

From initial consultation to final certification - we guide you through every step

Assessment of your hazardous location requirements, site classification, and regulatory needs

Detailed hazard and risk assessment, zone classification, and protection concept selection

Custom solution design, technical documentation, and compliance verification

Prototype testing, performance validation, and safety verification

Submission to notified bodies, certification management, and regulatory approval

Installation support, commissioning, and ongoing compliance maintenance

We have worked helped our clients to get certified for hazardous locations across multiple industries

LED fixtures, floodlights, and emergency lighting systems for Zone 1/2 and Class I Div 1/2 applications

Specialized luminaires for offshore platforms, refineries, and chemical plants with explosion-proof protection

Combustible gas detectors, toxic gas monitors, and multi-gas detection systems for continuous monitoring

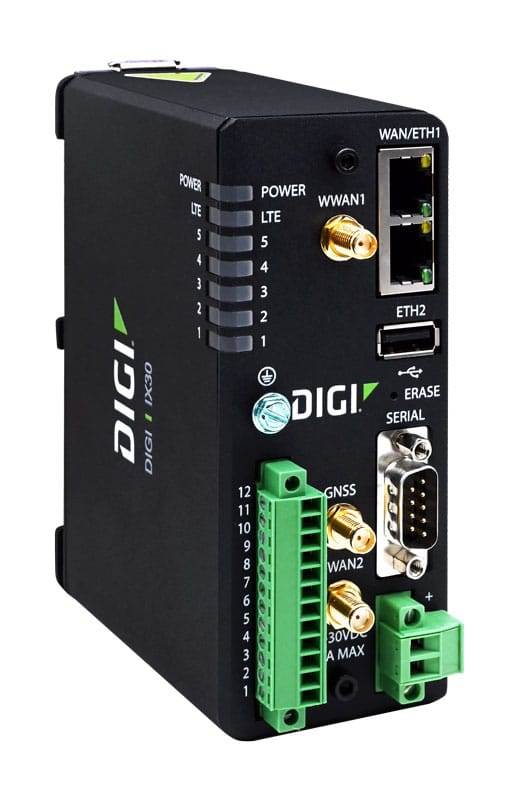

Industrial IoT communication hubs for remote monitoring and data collection in explosive atmospheres

Level measurement and safety laser scanners for tank gauging and perimeter protection systems

Ruggedized networking equipment for secure data transmission in hazardous industrial environments

Intrinsically safe smartphones and tablets for field operations and maintenance in explosive areas

Process control panels, motor control centers, and automation equipment for hazardous locations

Battery packs, UPS systems, and portable power solutions for hazardous area applications

Ready to discuss your hazardous location project? We get back to you the same day

hazloclabssales@gmail.com

+1 (972) 383 9097

Dallas, TX

Global Services Available